As of October 1st, 2023, the NCC is changing. All class 1A buildings within 10km of breaking surf designed to use structural SHS steel posts, piers, and stumps must have a minimum zinc coating of 225 grams per meter squared, per side. Uni-Pier has ensured that all of our products are designed and manufactured in accordance with the NCC and relevant Australian Standards for corrosion protection.

This change means that structural engineers, building designers, and builders must ensure their design and specifications comply with these new changes.

- At the construction certificate stage, certifiers will be required to determine the corrosivity category of the new building works

- Structural engineers and building designers will be required to ensure that the zinc coatings on structural steel SHS posts, piers, stumps, or columns are in accordance with the NCC changes

- Builders will need to demonstrate that the works have been constructed in accordance with the approved design and specifications by way of certification from their supplier or manufacturer

Currently, only one Australian manufacturer has an entire range of structural steel sub-floor products for class 1A buildings with a minimum coating of 390 grams per meter squared per side. And at Uni-Pier, we’re proud of the fact that it’s us.

Changing Requirements for Corrosion Protection of Steel Piers and Stumps

Steel posts, piers, and stumps are an increasingly popular alternative to traditional concrete stumps, providing a cost-effective, and environmentally-friendly alternative to builders. However, it is crucial to ensure that the steel piers and stumps are designed, manufactured, and installed in accordance with the National Construction Codes (NCC) and relevant Australian Standards.

It has been discovered that a significant number of Class 1A buildings within coastal areas of Eastern Australia have been constructed on steel piers and stumps without due consideration to the corrosivity of the location, and therefore are left without adequate protection. This lack of consideration can lead to a number of problems, including:

- Early and costly re-stumping of buildings and homes

- Rectification of cracked floors and wall tiles in bathrooms

- Rectification of damage to waterproof membrane in wet areas

- Re-fitting doors throughout the house including internal and external doors

- Re-painting the house where cracks appear on the inside and outside the house

- Replacing or repairing hot- and cold-water connections, including stormwater, sewerage pipes, and electrical connections

Certifier Requirements for Corrosion Protection of Steel Piers and Stumps

The public or private Certifiers must ensure the corrosion protection of steel piers and stumps of Clause 6.3.9 of BCA Volume Two 2022 states:

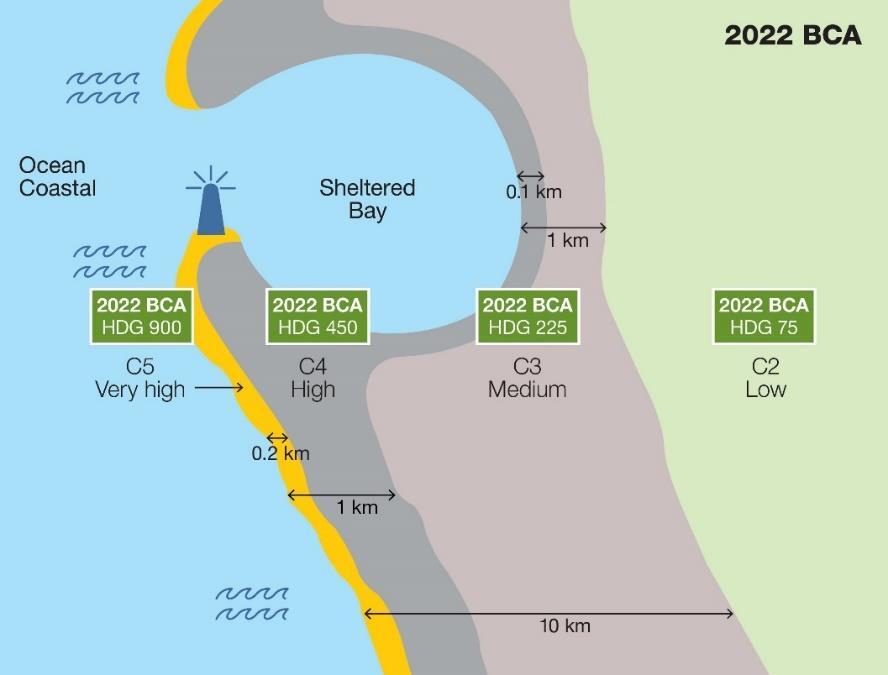

- At the Construction Certificate stage, determine the corrosivity category of the location of the building (Low, Medium, High, Very High, or C1, C2, C3, C4 & C5 as defined below). For further information refer to Section 3 of AS 4312: 2019 Atmospheric Corrosivity Zones in Australia.

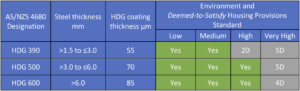

- Ensure that the architect’s and engineer’s designs specify suitable corrosion protection of the structural posts, for the corrosivity environment. For Hot Dip Galvanised steel members: The table below shows which readily available materials meet the requirements. If no certificate is available, then measure the HDG coating thickness. HDG coatings of all types are relatively straightforward to access via the use of a non-destructive coating gauge, even if no certification for the supplier is available.

For duplex and painted protective coatings: Document the certificate from the painter, or document evidence from the builder of the materials used, and measure the overall coating thickness. Paint systems must be in accordance with AS/NZS 2312.1 2014 Guide to the protection of structural steel against atmospheric corrosion by the use of protective coatings Part 1: Paint coatings.

- For paint (including duplex coatings), evidence of the surface preparation, paints used and the coating thickness for each type of paint will be required to assess conformance. Practically, a certificate from the paint applicator (if done in the factory), or evidence of the paint materials used by the builder (if done on-site) will be required.

- Certifiers are encouraged to utilise Section 12 of the Environmental Planning and Assessment (Development Certification and Fire Safety) Regulation 2021 to compel anyone involved in the design phase to provide any information the certifier considers necessary to properly consider the application.

- At the Occupation Certificate stage, ensure that the builder can demonstrate that the works have been constructed in accordance with the approved designs and specifications. This can be in the form of a statement from the builder with supporting evidence of the materials used. Where the steel has been cut, the builder must confirm/verify the steel thickness and class of galvanization and demonstrate that all cut edges are repaired to the standard of the original corrosion protection. Look for rust or repairs to welded areas, cut ends, and other damage. Obtain evidence that the repairs provide equivalent protection. This may include sighting the paint that was used or, for large areas of damage, measuring the coating thickness in the repaired area. If the damage has not been repaired, the product does not meet the requirements.

- Certifiers are encouraged to utilise Section 38 of the Environmental Planning and Assessment (Development Certification and Fire Safety) Regulation 2021 to compel anyone involved in the construction phase to provide any information the certifier considers necessary to properly consider the application.

Still not sure what’s what? Reach out to our team of technical experts today, and we can help you in the right direction for planning your next project.

Author – Kerry Bennett

Kerry Bennett revolutionised the Australian building industry in 1992 with the invention of Uni-Pier, an innovative steel height-adjustable underfloor support system. In 2002, Kerry went on to invent Benex, clinching the New Inventors Award in 2008 and the Australian Business Award for Best New Product in 2009.